manufacturing execution system

Systematic Introduction

|

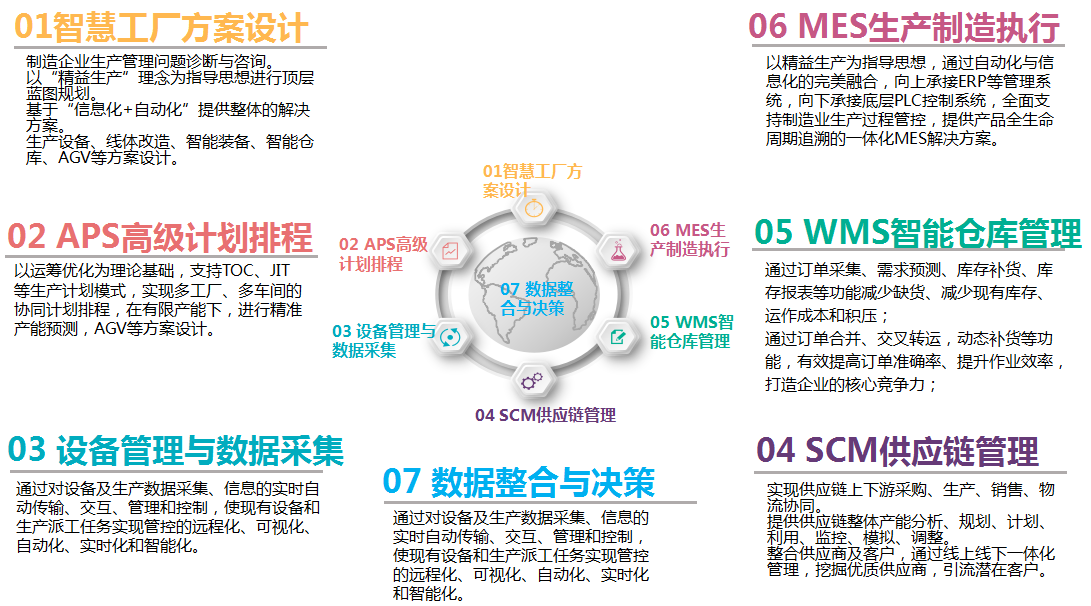

The CPS (Cyber Product System) system independently developed by Chengda can combine the existing information platform of the enterprise with the existing information platform of the enterprise and the two latest technologies of the Internet of Things and the mobile Internet, which can comprehensively enhance the deep integration of informationization and industrialization. Provide platform support. The CPS platform covers manufacturing execution management, precision supply chain management, warehouse management, equipment management and data collection, APS scheduling, big data integration and decision making. The system sensing layer can quickly collect basic data information such as raw materials, products, processes, equipment, personnel, etc., and fully realize product traceability and real-time production data. The system can fundamentally solve the "island" problem of the enterprise's existing information system, not only realizes the product life cycle quality traceability control and the interconnection of production equipment, but also helps the enterprise realize the transition from extensive management to refined management. , bringing refined management ideas into every important part of production management. |

業(yè)務(wù)范圍

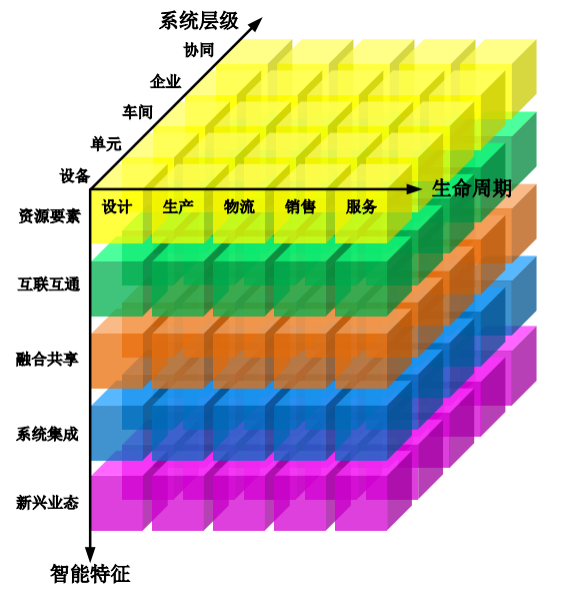

智能制造體系架構(gòu)

|

生命周期:是指從產(chǎn)品原型研發(fā)開始到產(chǎn)品回收再制造的各個(gè)階段,包括設(shè)計(jì)、生產(chǎn)、物流、銷售、服務(wù)等一系列相互聯(lián)系的價(jià)值創(chuàng)造活動(dòng)。 系統(tǒng)層級(jí):是指與企業(yè)生產(chǎn)活動(dòng)相關(guān)的組織結(jié)構(gòu)的層級(jí)劃分,包括設(shè)備層、單元層、車間層、企業(yè)層和協(xié)同層。 智能特征:是指基于新一代信息通信技術(shù)使制造活動(dòng)具有自感知、自學(xué)習(xí)、自決策、自執(zhí)行、自適應(yīng)等一個(gè)或多個(gè)功能的層級(jí)劃分,包括資源要素、互聯(lián)互通、融合共享、系統(tǒng)集成和新興業(yè)態(tài)等五層智能化要求。 |

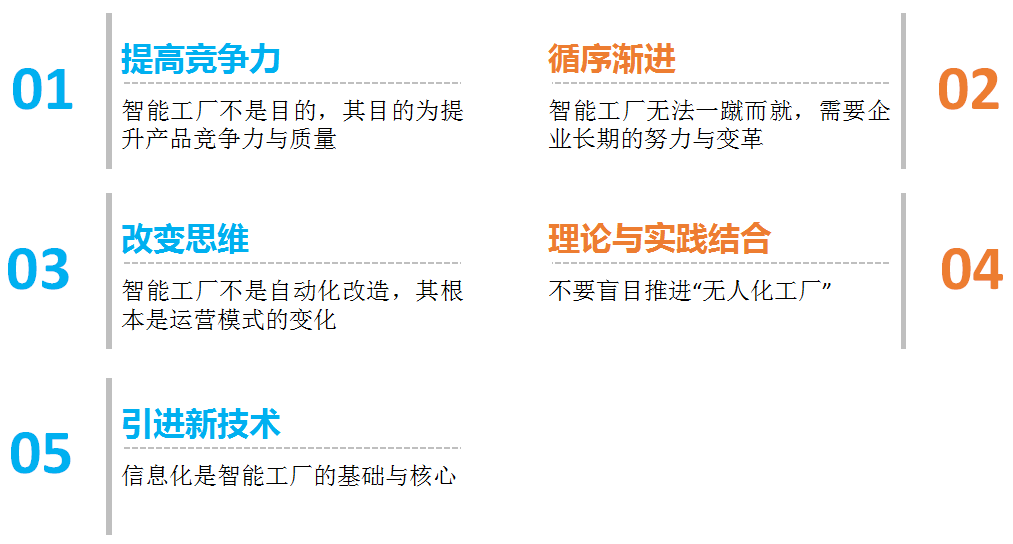

智能制造的思路

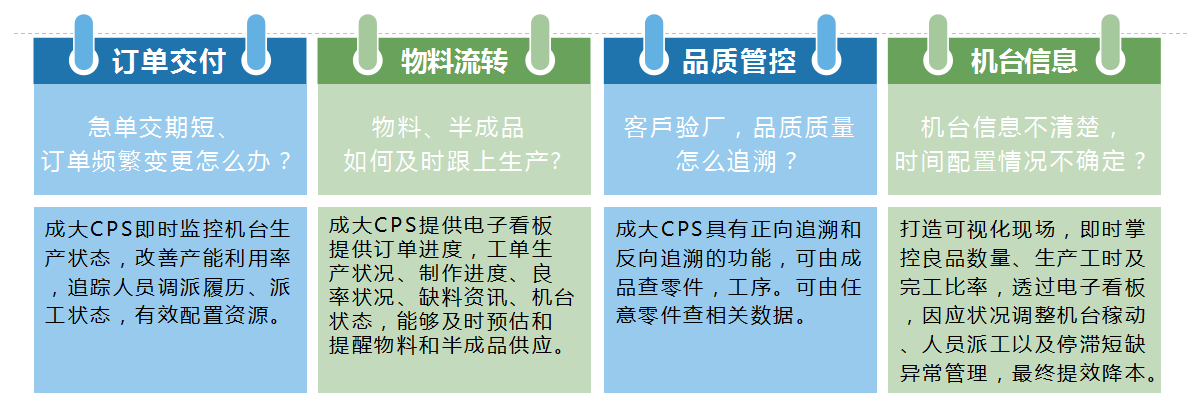

困擾車間的問題?

| 我們幫您解決的問題 |

及時(shí)準(zhǔn)確將計(jì)劃以及變更信息發(fā)布到制造現(xiàn)場(chǎng) 及時(shí)準(zhǔn)確將計(jì)劃以及變更信息發(fā)布到制造現(xiàn)場(chǎng) |

監(jiān)控產(chǎn)品的整個(gè)作業(yè)流程,給作業(yè)人員足夠的信息指導(dǎo),實(shí)現(xiàn)防呆管理,避免或預(yù)防問題的發(fā)生 監(jiān)控產(chǎn)品的整個(gè)作業(yè)流程,給作業(yè)人員足夠的信息指導(dǎo),實(shí)現(xiàn)防呆管理,避免或預(yù)防問題的發(fā)生 |

提高產(chǎn)線現(xiàn)場(chǎng)對(duì)各種變更的響應(yīng)以及反饋速度 提高產(chǎn)線現(xiàn)場(chǎng)對(duì)各種變更的響應(yīng)以及反饋速度 |

實(shí)現(xiàn)對(duì)產(chǎn)品、物料的序列、批次追蹤與管理 實(shí)現(xiàn)對(duì)產(chǎn)品、物料的序列、批次追蹤與管理 |

實(shí)時(shí)記錄制造過程中的在制、工時(shí)、人員、設(shè)備等信息 實(shí)時(shí)記錄制造過程中的在制、工時(shí)、人員、設(shè)備等信息 |

給管理人員提供對(duì)作業(yè)現(xiàn)場(chǎng)進(jìn)行可視化監(jiān)控管理的工具 給管理人員提供對(duì)作業(yè)現(xiàn)場(chǎng)進(jìn)行可視化監(jiān)控管理的工具 |

給管理人員提供改善制造流程、工藝的各種及時(shí)準(zhǔn)確的數(shù)據(jù) 給管理人員提供改善制造流程、工藝的各種及時(shí)準(zhǔn)確的數(shù)據(jù) |

實(shí)現(xiàn)倉(cāng)庫(kù)物料的智能管理,追溯物料的走向,提高倉(cāng)庫(kù)的周轉(zhuǎn)率 實(shí)現(xiàn)倉(cāng)庫(kù)物料的智能管理,追溯物料的走向,提高倉(cāng)庫(kù)的周轉(zhuǎn)率 |

智能化管理工程文件,節(jié)省運(yùn)營(yíng)成本,優(yōu)化管理流程,提升業(yè)務(wù)處理效率 智能化管理工程文件,節(jié)省運(yùn)營(yíng)成本,優(yōu)化管理流程,提升業(yè)務(wù)處理效率 |

歸納/整合/分析過程信息,為高層決策提供全面及時(shí)準(zhǔn)確的數(shù)據(jù) 歸納/整合/分析過程信息,為高層決策提供全面及時(shí)準(zhǔn)確的數(shù)據(jù) |

創(chuàng)造三大核心價(jià)值

| 降本:成本是影響企業(yè)獲利的關(guān)鍵,包含人工成本,刀具成本、庫(kù)存成本等,透過智能化做到精細(xì)化管理達(dá)到庫(kù)存降低,壓縮無效工時(shí)提高人均產(chǎn)值,高度信息透明化提高刀具管理,降低刀具損耗比。 |

| 增效:成大CPS為實(shí)現(xiàn)工廠智能化核心,承上啟下,整合人機(jī)料法環(huán)信息。 例如針對(duì)每一個(gè)模具,從上模到入庫(kù)、出庫(kù),以及模具的保養(yǎng)等信息,都在系統(tǒng)里得到實(shí)時(shí)顯示和統(tǒng)一管理,達(dá)到管理信息透明化,提升生產(chǎn)管理效率。 |

| 提質(zhì):成大CPS整合IT與OT層信息,不僅提高數(shù)據(jù)正確性、即時(shí)性,加快回應(yīng)速度,完整紀(jì)錄質(zhì)量檢驗(yàn)過程,透過系統(tǒng)進(jìn)行查詢,快速響應(yīng)客戶,完成品質(zhì)追溯;做到刀具壽命預(yù)警機(jī)制,降低產(chǎn)品質(zhì)量異常等。 |

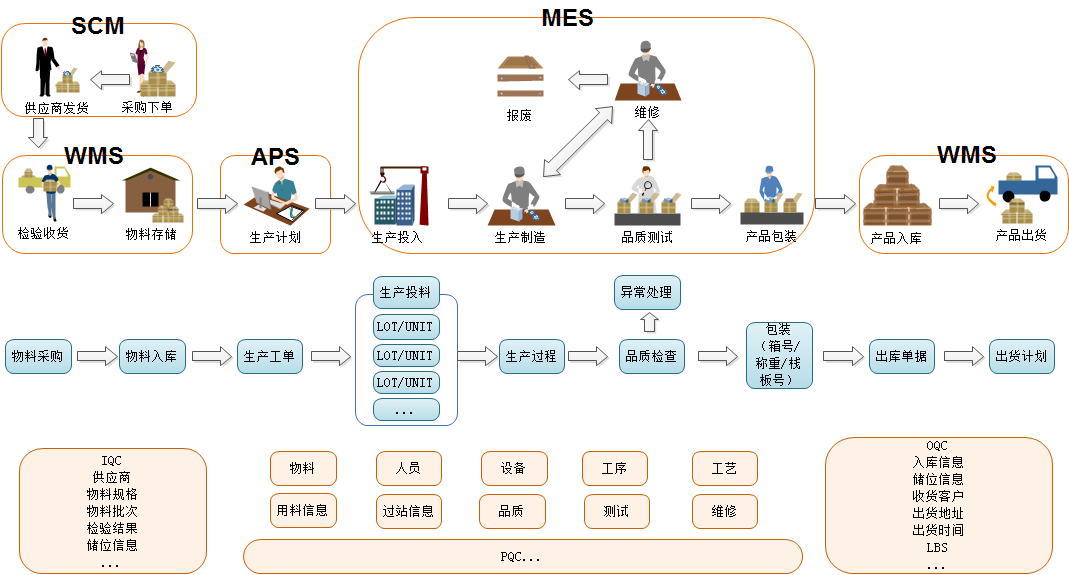

總體架構(gòu)

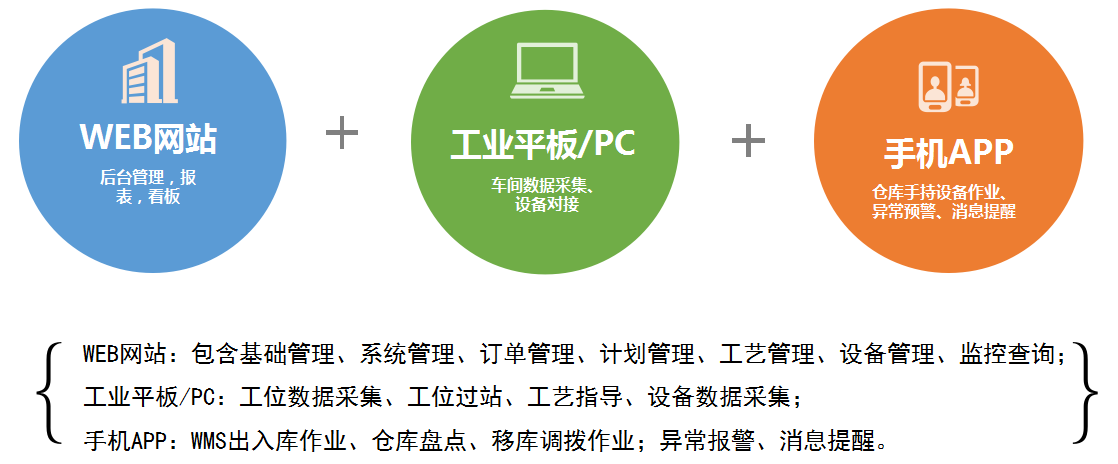

展現(xiàn)形式

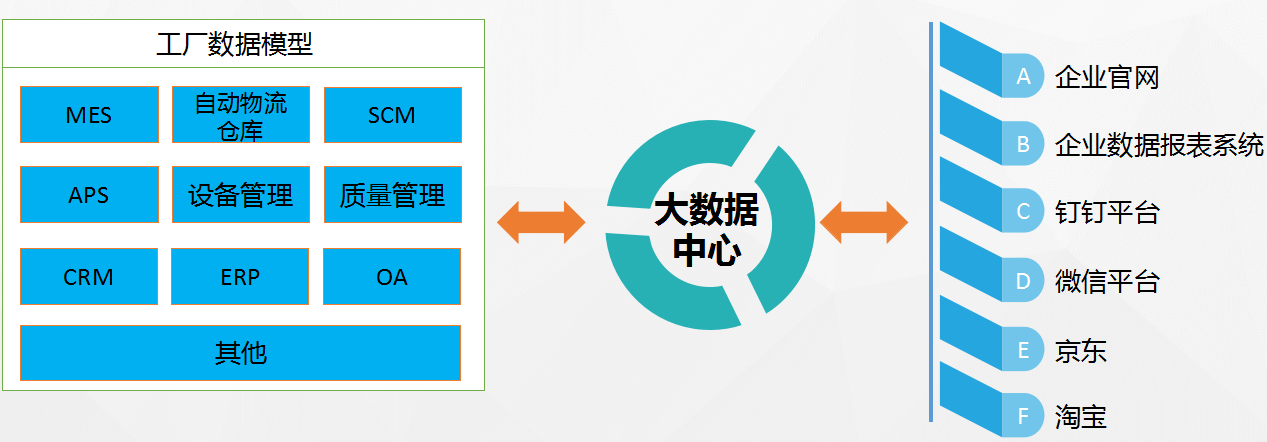

系統(tǒng)整合

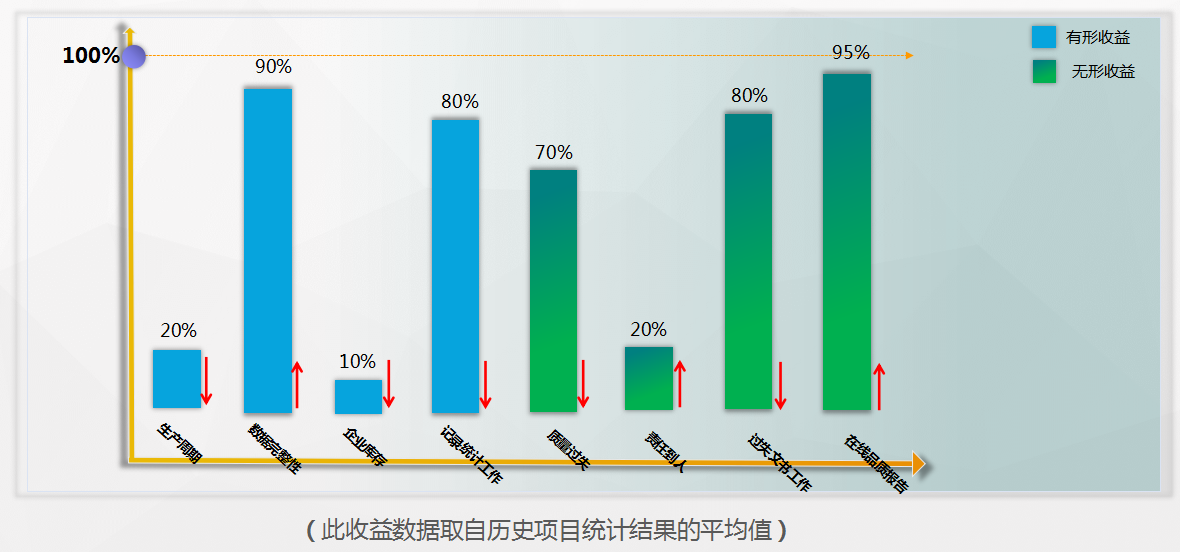

系統(tǒng)收益

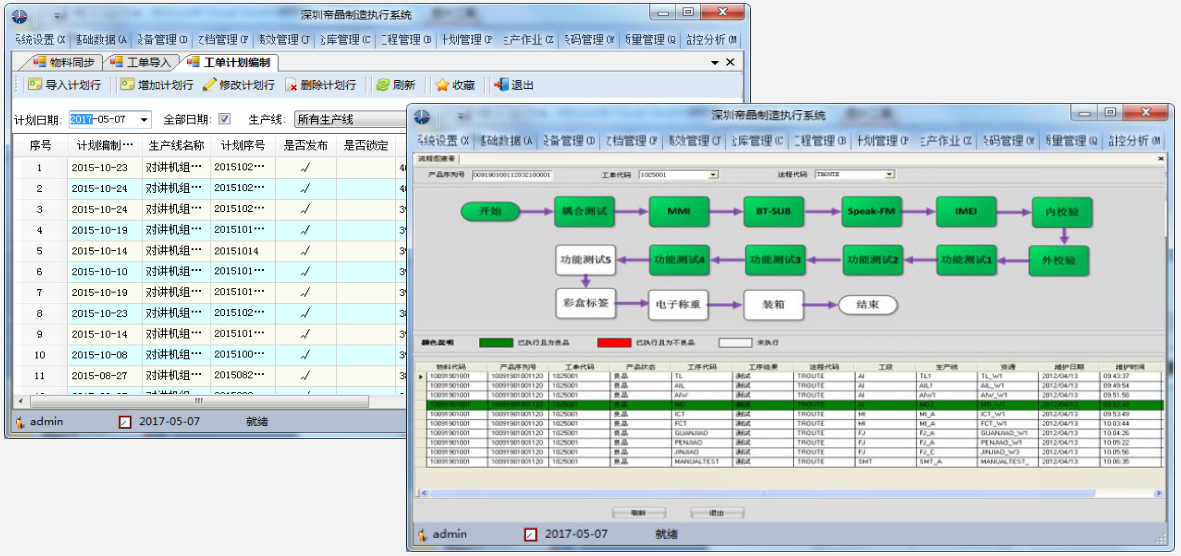

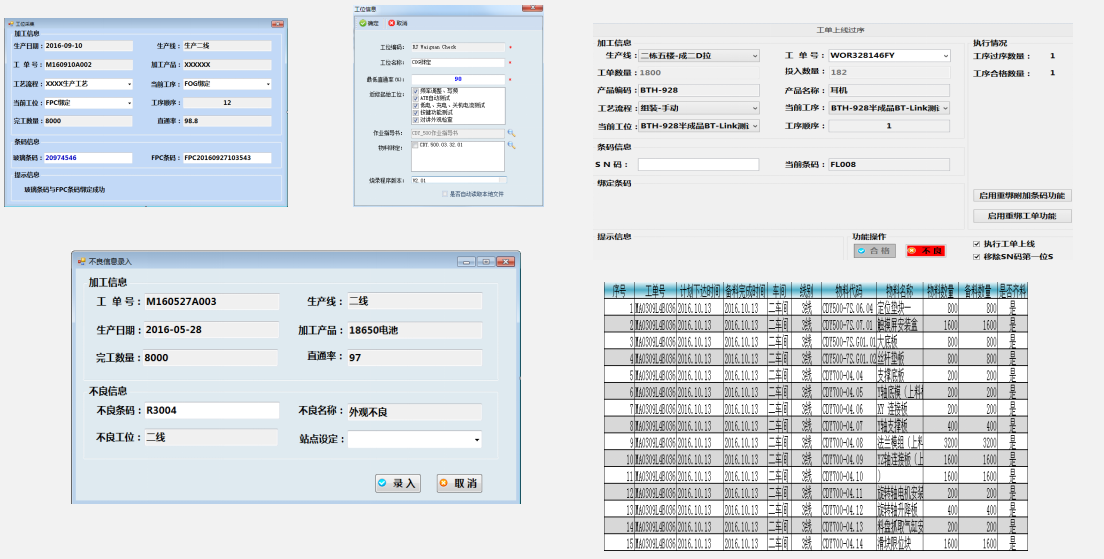

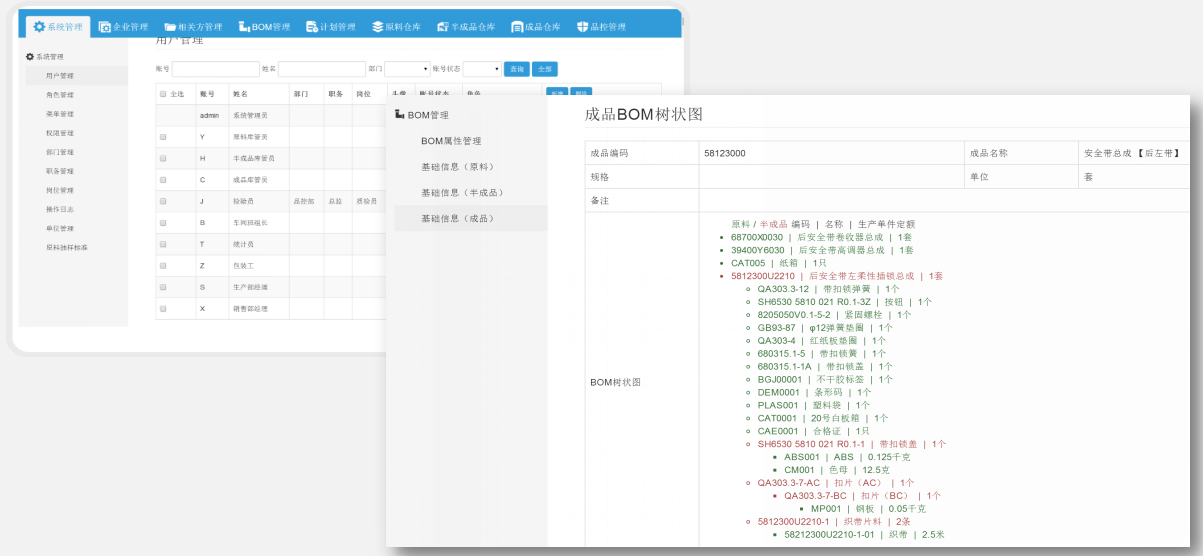

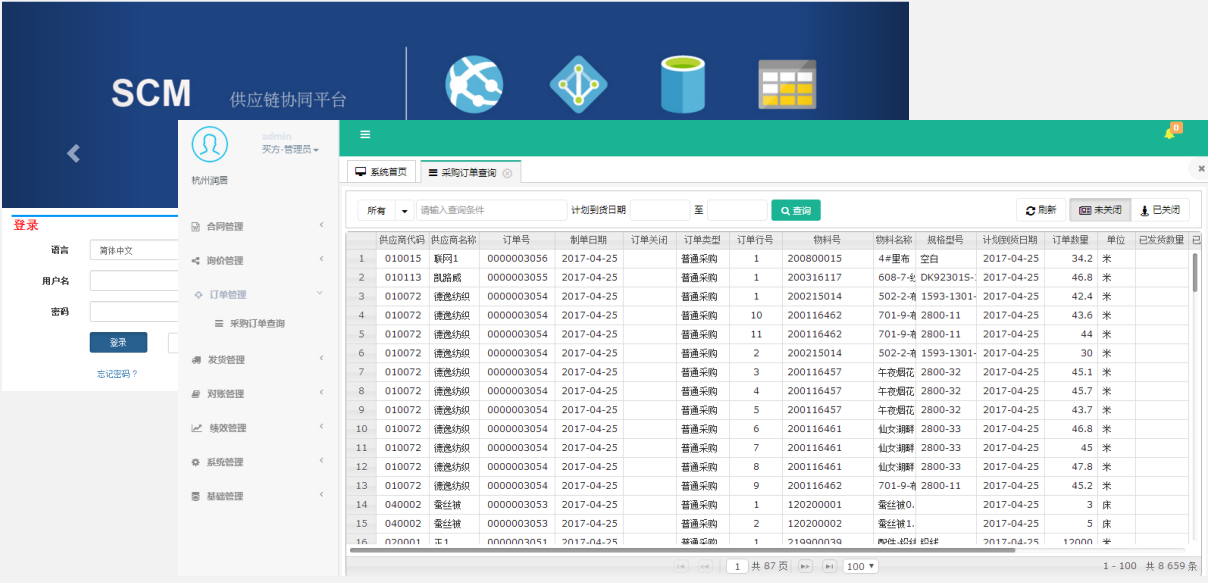

界面展示

客戶端示意圖1

客戶端示意圖2

WEB示意圖1

WEB示意圖2

WEB示意圖3

APP示意圖1

APP示意圖2

釘釘示意圖1

釘釘示意圖2

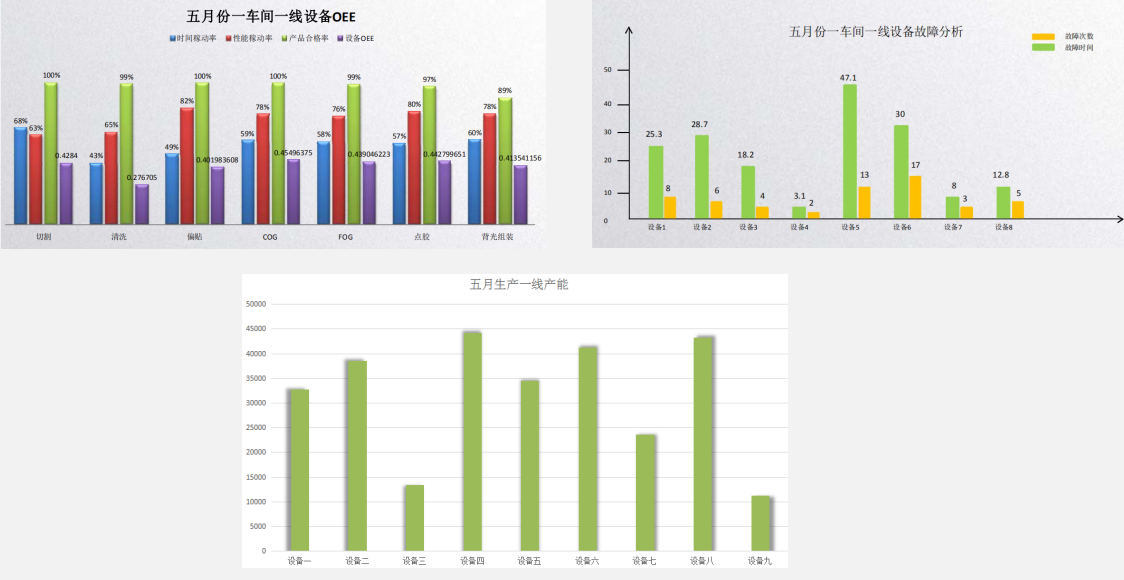

圖表示意圖1

圖表示意圖2

圖表示意圖3

看板示意圖1

看板示意圖2

粵公網(wǎng)安備 44030602001486號(hào)

粵公網(wǎng)安備 44030602001486號(hào)